Battery Thermal Management System

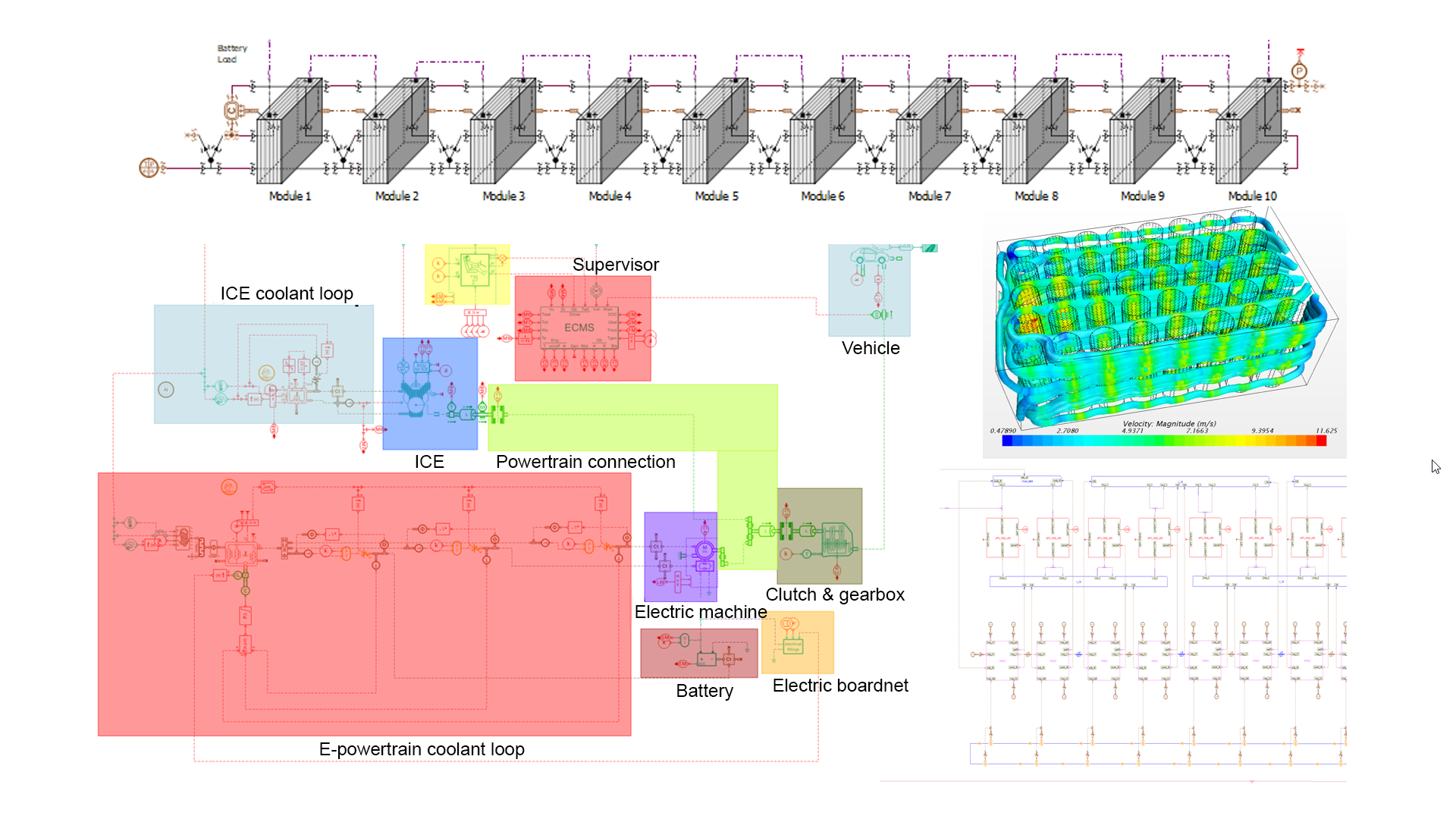

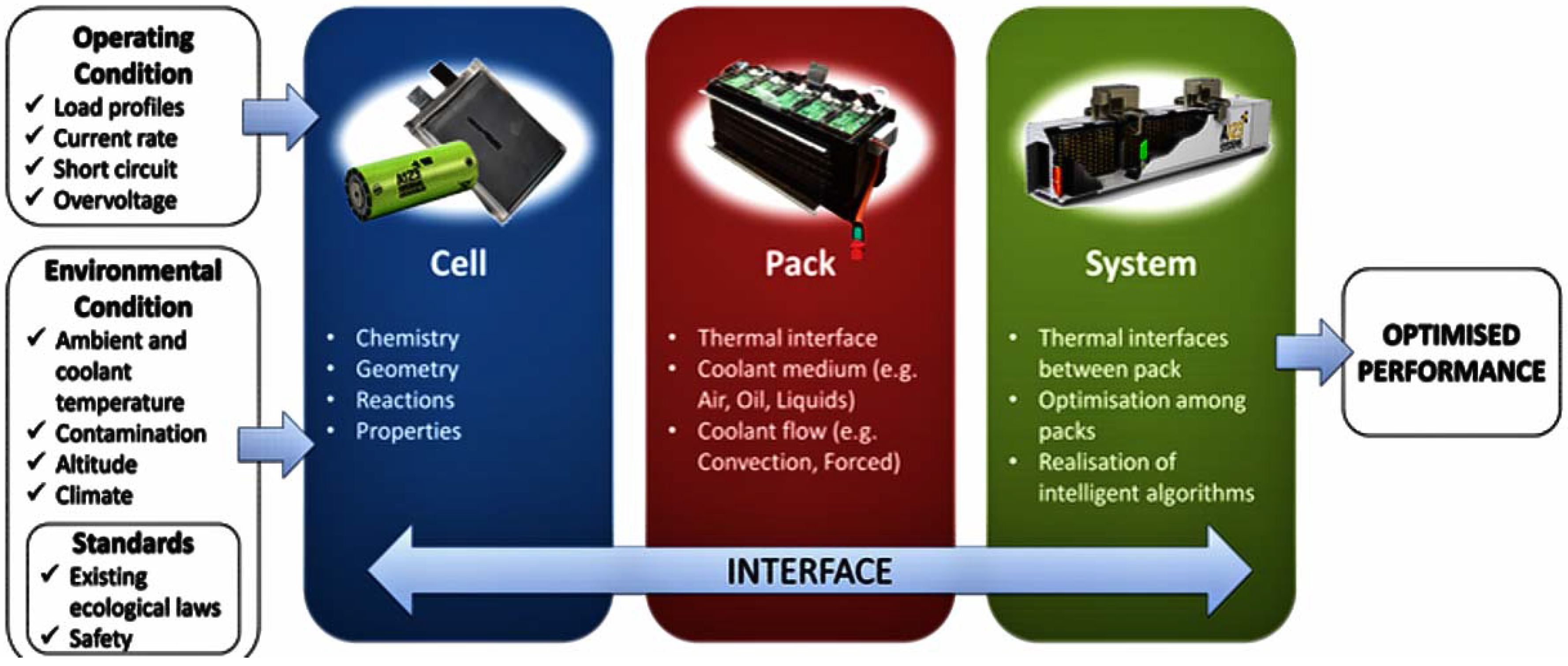

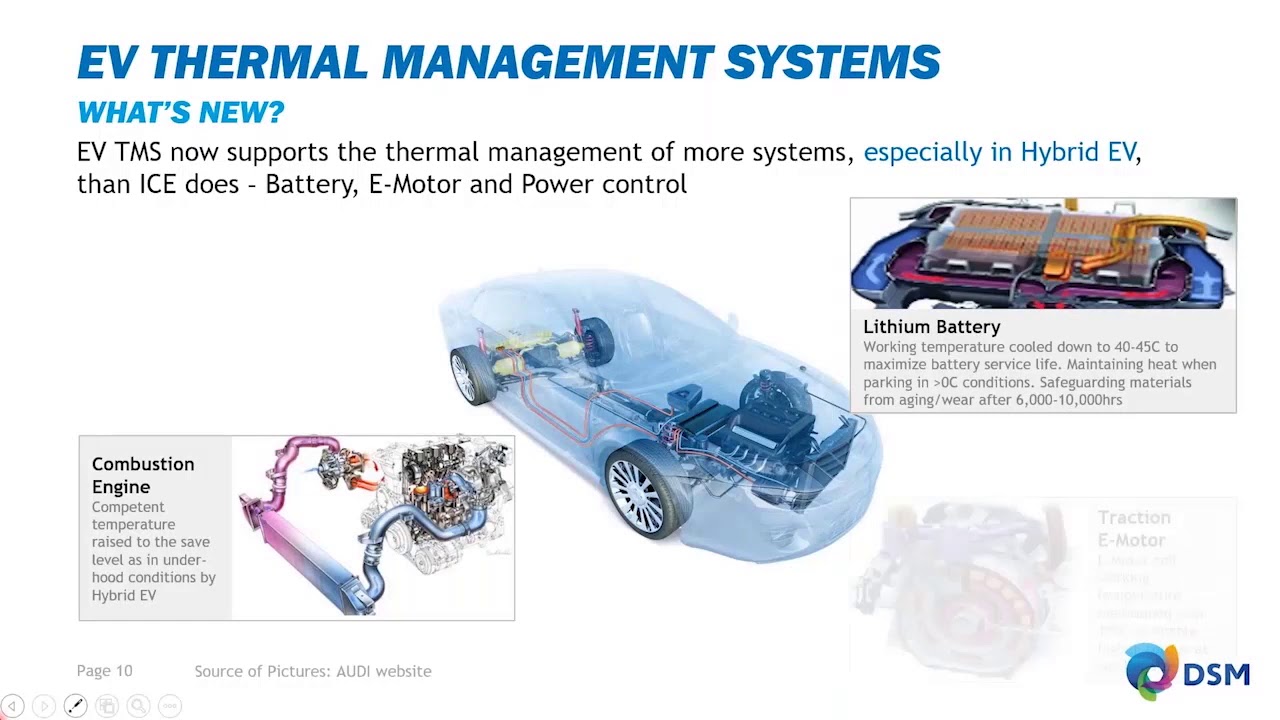

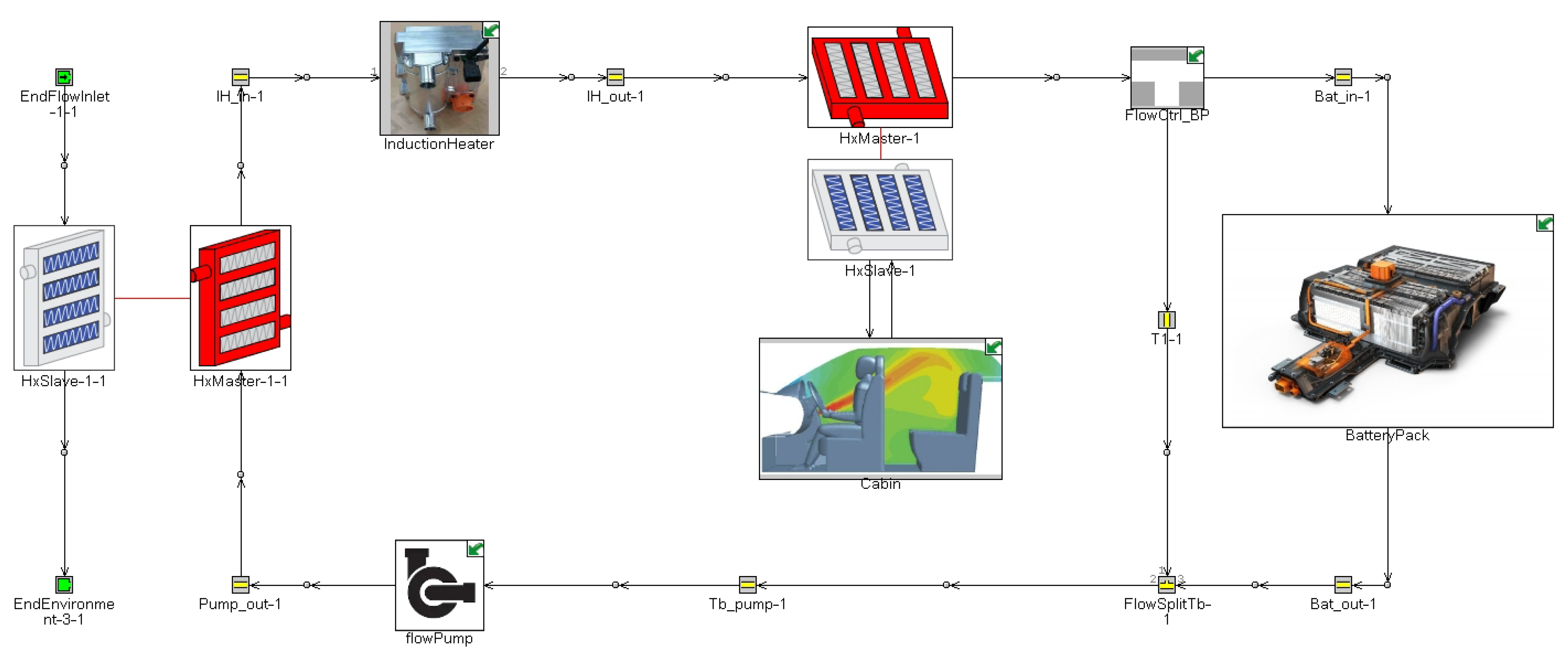

Battery thermal management system. Heightening popularity of battery electric vehicles BEVs and plug-in. The hybrid thermal management system consists of different types of media such as liquid air and other cooling media combined with the battery system. This presentation examines the issues concerning thermal management in electric drive.

Battery Thermal Management System BTMS The Modine Battery Thermal Management System is a complete thermal system solution that maintains the critical operating temperature ranges of vehicle batteries. What is a Battery Thermal Management System. 1 to keep batteries working under suitable conditions and improve the electrical performance and battery life and 2 to prevent thermal runaway from occurring.

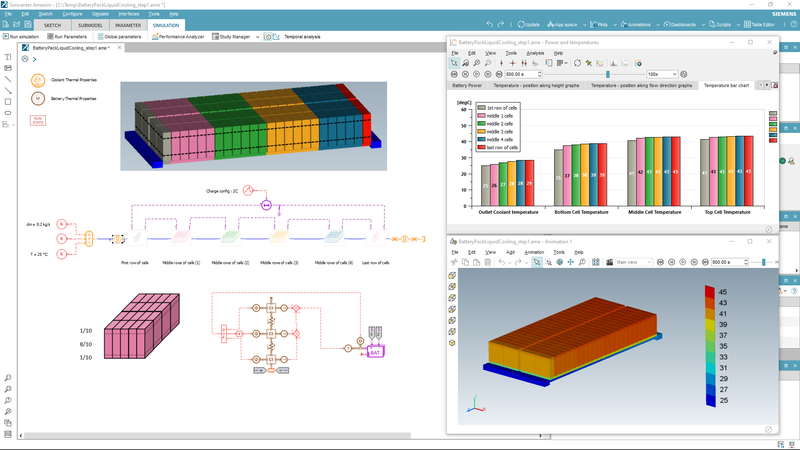

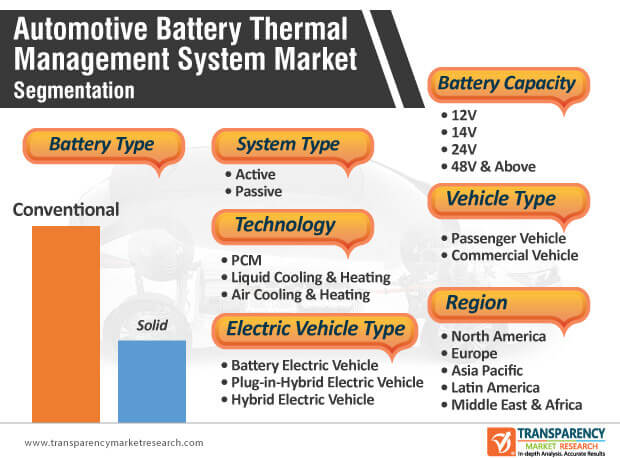

Battery Thermal Management System Market Overview. Working conditions for batteries referred to as a battery thermal management system BTMS. Battery thermal management systems BTMS are methods employed to keep the temperature in a battery pack within a fixed range ideally between 20 and 40 C avoiding excessive fluctuations and.

Battery thermal management system. A well-designed battery thermal management system will ensure good battery performance safety and better capacity. Global Battery Thermal Management System Market report emphasizes on the detailed understanding of some decisive factors such as size share sales forecast trends supply production demands industry and CAGR in order to provide a comprehensive outlook of the global market.

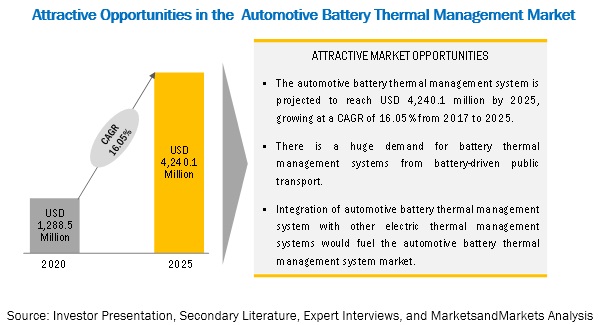

The electric vehicle battery thermal management system EV BTMS market is poised to grow by USD 1025 billion between 2020 and 2025 according to Technavio. Thus the function temperature of PCM should be higher than the ambient temperature. The main goal of a battery thermal management system is to maintain a battery pack at an optimum average temperature as dictated by life and performance trade-off.

Battery thermal management system plays a vital role in improving battery efficiency and performance which is further accelerating the adoption of these systems in the market. PDF Version Also Available for Download. The market is fragmented and the degree of fragmentation will decelerate during the forecast period.

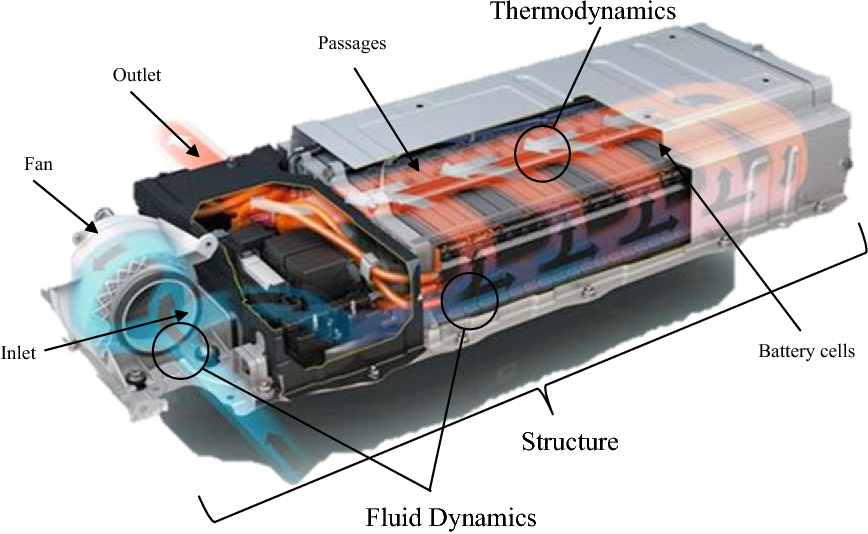

For example an electric fan can be enclosed inside a battery or module to circulate air inside the battery which can be combined with a heat exchanger such as an aluminum support pipe or a Partie device to allow air to flow over the surface. Natural air cooling or forced air.

Thus the function temperature of PCM should be higher than the ambient temperature.

To recap a well designed Battery Thermal Management System should. Methods like liquid cooling indirect or direct. Dana Inc DOBER DuPont de Nemours Inc Gentherm Inc Infineon. This is especially dangerous when using lithium-ion batteries. Automotive battery thermal management system market set to exhibit a staggering CAGR of approximately 36 through 2026. From the outside a thermal management system TMS implemented in battery packs can help to relieve the rapid temperature rise and improve the stability and safety of Li-ion batteries during charge and discharge procedures. Battery thermal management system. Battery dissipates the heat to PCM. Maintain temperature within 5 C to 30C.

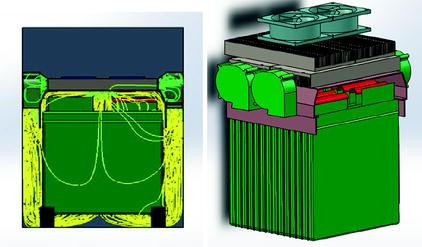

In this paper heat pipe based thermal management system for high power battery with eight prismatic cells has been proposed designed and tested for heat load up to 400 W. There are two main functions of BTMSs. Design solutions are available for both active and passive cooling circuits. BTMS is a mandatory for lithium-ion battery systems at high. Natural air cooling or forced air. Please complete the form below to receive technical information on the Grayson Battery Thermal Management System. This is especially dangerous when using lithium-ion batteries.

Post a Comment for "Battery Thermal Management System"